Introduction

In my previous post I hd mentioned that having got the 3D printer ready to go again, I planned to print the case for my Raspberry PI. After viewing some of the cases on Thingiverse I located one that had been designed with four wall mounts.

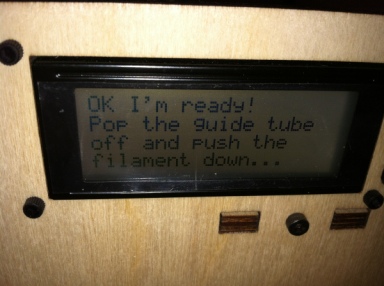

In my initial attempt to export the image to the SD card, everything had seemed to work correctly, however the MakerBot was unable to view it. So during my lunch hour today I removed the file from the SD card and started over.

Exporting the case to SD card

My first step was to load the top portion of the case’s .stl file into ReplicatorG. Using the 3D rendering of the image I was able to align the case top so that it was positioned in the middle of the axis. Once this was complete I then exported the file to Gcode. Finally I edited the Gcode so the heat of the base plate would be 120 degrees F.

I then followed the steps above for the bottom portion of the case.

The images were now ready to export to SD format. Using the option on the menu I exported directly to my SD card, and also shortened the rather long names of the files in case this contributed to the MakerBot not being able to view them.

Ejecting the SD card I was now ready to give printing another try.

Printing the case

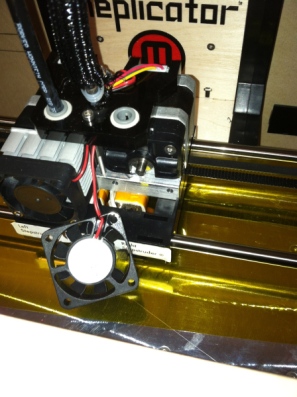

Loading the SD card into the MakerBot I could now view the files on the menu and so set the top to print. I left the printer to do its thing and checked back in on it a couple of hours later. As you can see in the picture below, the printing was successful:

Raspberry PI case

Raspberry PI top

Raspberry PI case

With the two pieces of the case complete my next job was to clean the lattice off the objects and try the Raspberry PI out to see if it fit.

Here you can see the case clipped together:

Completed case

I would recommend for the next steps having some kind of tray to put the case on, an X-acto knife and some sand-paper or a tool to smooth off the plastic (the later being something I didn’t have at hand at home, so I’ll need a trip to Home Depot).

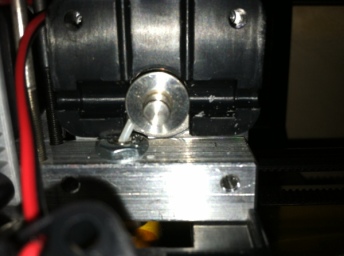

Most objects are printed onto a lattice base, so your first job will be to remove this.

As you can see below, the lattice that the objects are printed on comes off pretty easily, you can snap this off with your hand right after you take the object out of the MakerBot.

Lattice

As a note: One thing I have noticed about the quality of the print – in general – is that the objects made on the MakerBot have a lot of rough portions that need to be cut or smoothed off. This takes a little while so with my RPI case I set some time aside this evening to work on cleaning it up.

Here you can see the bottom portion of the RPI case:

Case bottom

Outside of the RPI case

Using an X-acto knife I gently removed the top layer on the case to reveal the better resolution layer below. However this is a tedious process and even with the X-acto knife didn’t give me the result I wanted. It is also messy so having a tray to catch the off-cuts was handy. At this point some sandpaper would have been useful. Since I didn’t have this at home, doing the final sanding off had to wait. Once I do this I also plan to spray paint the case, which will be the subject of another post.

Having done a best of a job as possible cleaning things up I now tried placing the RPI inside the bottom section. The RPI fitted in here no problem. I now tried to place the top onto the RPI and close the case. At this point I noticed that one of the plastic lips inside the case was catching on the RPI near the SD card port. Taking the X-acto knife I cut this portion off and now the case closed perfectly.

You can see the final result here:

RPI in the case

So as you can see above, we have our first attempt at a printed Raspberry PI case complete. Once I finish off the aesthetics of the case, I will then be able to attach it to the wall and wire it up to my home network. I still have some configuration to complete on the RPI in the area of HTSQL installation which I will be blogging about soon.

All in all the process has been a great learning experience and given me a number of avenues to investigate, including how to ensure a better resolution and quality of print on future 3D objects.

It’s also been the first project that has been successfully completed on our co-op’s MakerBot leading to us now feeling comfortable with everyone jumping in and printing their own creations.

With regards to cases, for the Arduino thermostat, I plan to design my own housing unit in Blender, which will also be the subject of a future blog posting.

Finally, if anyone has any suggestions of improving the print quality, please feel free to comment below!